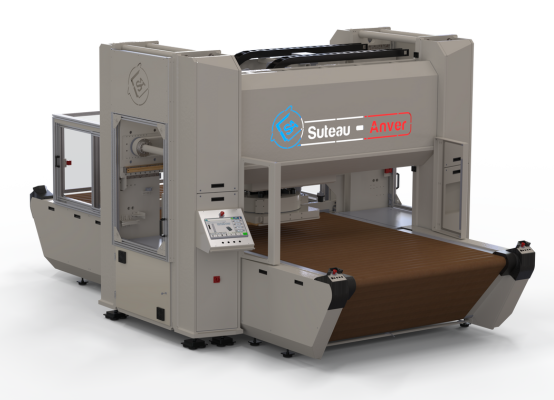

CNC traveling head die-cutting machine – model SA 121-cn

In this video, you can clearly see the fluid, precise movement of the moving head, the heart of the cutting system.

The SA 121-cn machine is a high-precision hydraulic press designed for cutting flexible and semi-rigid materials, whether in sheet or roll form. The cutting die is mounted underneath the traveling head, ensuring enhanced stability and precision during the cutting process.

Key features

The cardboard cutting belt provides a cost-effective and practical alternative: it allows for significant savings, reduces maintenance, and is easily replaceable for optimized use.

The nesting software optimizes the placement of cuts, minimizing material waste and improving production efficiency.

It can be equipped with an automatic storage, enabling easy tool changes and allowing multiple cutting shapes to be integrated within the same production cycle.

Thanks to its advanced system, the SA 121-cn can cut multiple layers of material simultaneously, ensuring high productivity and optimized output.

Advantages

- Cardboard cutting belt: costeffective and easy to replace

- Servo-pump integrated into the

traveling head: requires little oil,

energy-efficient and reduces noise - Operator protection secured by a cell barrier

- Robust in echanical welding

- User-friendly and intuitive human-machine interface (HMI)

- HMI position configurable on the

left or right, bility to create and store production programs

- Multi-languages

- Cuts simple or complex shapes

with minimal material waste - High cutting precision

- Constant parallelism

- Minimal cleaning required

- Low maintenance requirements

- Easy maintenance access

- Hydraulic power unit and electrical

panel integrated into the machine - Tool loading possible from the left or right

Multiple Applications

- Rubber

- Cardboard

- Leather

- Felt

- Insulation

- Gasket

- Cork

- Carpet

- Foam

- Paper

- Plastic

- PVC

- Flooring

- Synthetic materials

- Textile

Sectors

- Aeronautics

- Furniture

- Automotive

- Composite

- Industry

- Bedding

- Leather goods

- Medical

- Packaging

- Thermoformed parts

- Point of sale

- Saddlery

Why choose Suteau-Anver?

With almost 80 years of expertise, Suteau-Anver is the trusted partner for manufacturers worldwide. Our commitment: to supply high-performance, innovative machines tailored to the specific needs of each customer.

Technical features

| Power supply | Three-phased 400V + Neutral + Earth |

| Electrical power | 16 kW |

| Control circuit voltage | 24 V |

| Pneumatic supply | 6 bars |

| Cutting speed | Between 50 and 200 mm/s |

| Adjustable stroke | Between 5 et 210 mm |

| Cutting power | 50 tons |

| Maximum daylight between the table and the beam without cutting block | 210 mm |

| Maximum tool dimensions | 850 mm x 850 mm |

| Usefull width | 1900 mm |

| Maximum material height | 110 mm |

| Fast descent/ascent speed | 200 mm/s |

| Maximum pace | Between 18 and 50 cuts/min may varry depending on the size & shape of the cuttings and the height of the material |

Options

- Remote maintenance

- Automatic tool change

- Other cutting power available

- Other tool dimensions available

- Other material width available

- Other type of conveyor belt

- System for collecting cut products: robot, unstacker and prehension