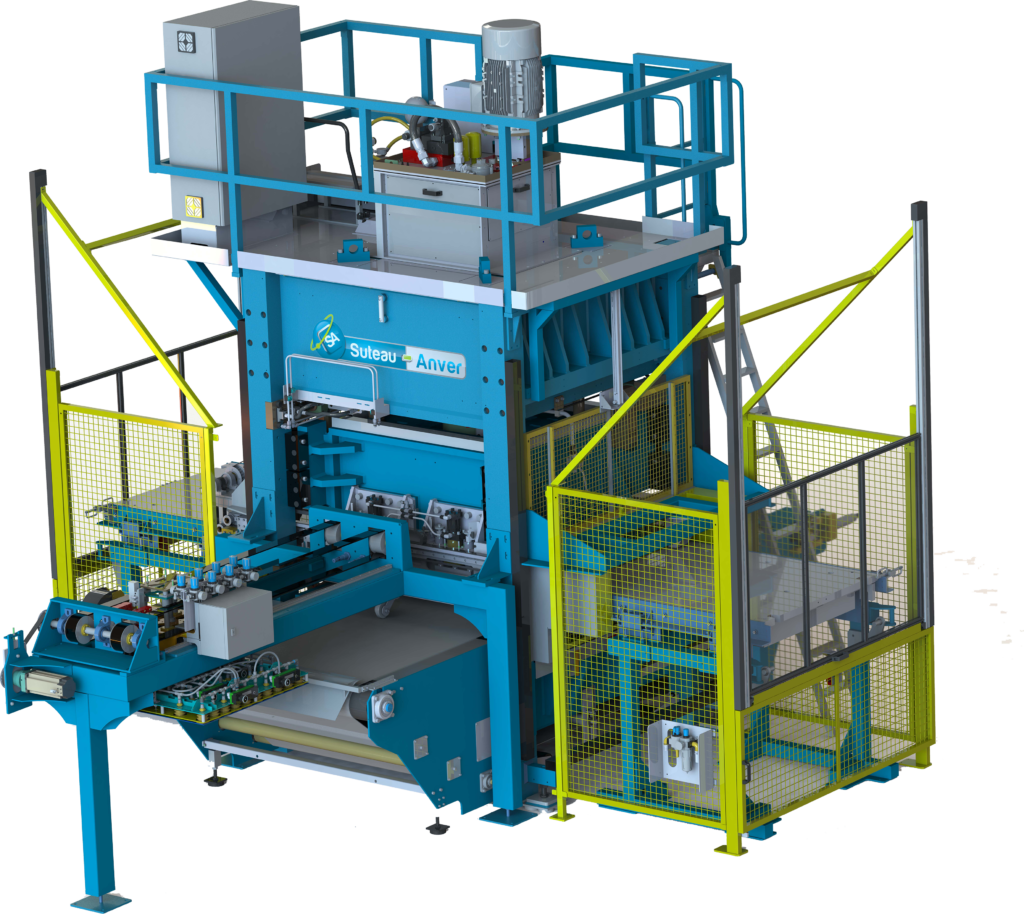

Die-cutting press with movable beam – Model VFS

SUTEAU-ANVER Movable Beam Hydraulic Die-Cutting Machine Model VFS: The Ultimate in Industrial Die-Cutting Solutions

Discover the pinnacle of die-cutting technology with the SUTEAU-ANVER Movable Beam Hydraulic Die-Cutting Machine Model VFS. As a leading die-cutting machine supplier, we take pride in offering industrial cutting solutions that embody precision, efficiency, and innovation. Our Model VFS is not just a standard die-cutting machine; it’s an advanced solution for various flexible materials.

Engineered with precision and durability, this heavy-duty cutting machine is ideal for industries requiring high-speed die-cutting and uncompromising accuracy. The hydraulic beam press technology, integrated with advanced hydraulic cutting equipment, ensures seamless operation and top-notch performance. This beam press cutting machine is meticulously designed to meet the rigorous demands of industrial applications.

This die cutting press with movable beam is the top of SUTEAU-ANVER’s range of presses, setting the benchmark in the industry internationally.

Designed and manufactured by SUTEAU-ANVER, this press is sturdy, accurate, silent and specially developed for cutting all non-metalic materials; its integrated hydraulic system makes it both highly efficient and productive.

Designed for mass production, your materials can be cut into rolls or sheets on a belt, or steel or polypropylene plate.

Made in a modern and innovative designing, the structure is made up of one fixed table and one fixed upper beam assembled to 4 vertical uprights. The movable beam is assembled to the upper beam by one hydraulic central cylinder which ensures the rising and the descent of this one. The beam guide is ensured on his 4 corners by celoron in contact with the 4 vertical uprights. This machine is designed to run with a cutting strain symmetrical in relation to the central cutting area.

The cutting bottom point is given by 4 mechanical stops. The adjustment of this stops according to the cutting die height is automatic and made during an adjustment phase. This stops are motorised by a moto-reducer and an electronic speed variator. After the adjustment phase, it’s possible since the controle screen to correct the position of the cutting point with an accuracy of 0.01 mm. The 4 posi-stops are integrated to the fixed table. On option, an air spray system allow to avoid the pollution risk of the upper side of the stops.

The stop point in upper position is also adjustable according the requested way between, the top of the material and the die blades. The adjustment can be made at all time with the control screen. The position is checked by a linear potentiometer with an accuracy of +/- 5 mm.

In order to ensure the safety of the operator during intervention under the movable beam, it’s possible to lock in hydraulic way the movable beam in upper position. This locking is automatic during the machine stop or during a die changing.

Key Features

- Industrial Die-Cutting Machine Excellence: Our die-cutting equipment sets the standard for industrial cutting solutions, offering unparalleled precision and efficiency.

- Beam Cutting Machine Innovation: The hydraulic cutting press in our Model VFS showcases cutting-edge beam cutting technology, ensuring consistent, high-quality cuts.

- High-Speed Die-Cutting Performance: Experience rapid production without sacrificing quality, thanks to our high-speed die-cutting capabilities.

- Precision Cutting Machine: Precision is at the heart of our design, making our Model VFS the best die-cutting machine for intricate and demanding tasks.

- Professional Die-Cut Machine: Tailored for professional environments, our machine offers robustness and reliability, standing as a testament to our reputation as a premier die-cutting machine manufacturer.

- Hydraulic Cutting Equipment: The integration of hydraulic technology guarantees smooth and efficient operation, reinforcing our status as a cutting machine supplier of choice.

Whether you are in the market for a die-cutting machine for sale or seeking comprehensive die-cutting solutions, the SUTEAU-ANVER Model VFS is your answer. Experience the synergy of advanced die-cutting technology and industrial-grade construction with our movable beam hydraulic die-cutting machine.

Technical features

| Electric energy: | 400 Volts threephase + Neutral + Earth 50hz |

| Power: | 11 KW to 30 KW according to the versions |

| Pneumatic energy: | Dry air 6 Bars |

| Cutting table width: | According to your needs |

| Cutting table depth: | According to your needs |

| Cutting power: | 100 to 500 tons |

| Maxi beam stroke: | 180 mm (other stroke on request) |

| Maxi daylight opening: | 200 mm (other daylight opening on request) |

Options

- Block / die rotation system

- Rectified tempered steel plate – Thickness 10 mm – Hardness 60 hrc

- Heating plate

- Die-holder

- Automatic cutting die loading and unloading from the belt

- Remote control module

- Automatic feeding systems

- Automatic outfeeding systems

Available versions