Receding head die-cutting press – Model XPM

Introducing the SA XPM Model – The Ultimate Hydraulic Die-Cutting Press for Industrial Applications

This receding head die-cutting press designed and manufactured by SUTEAU-ANVER is solidly-built, accurate and silent, and specially designed for cutting any non-metallic materials, depends on its built-in hydraulics.

Experience unparalleled precision and efficiency with our SA XPM model, a state-of-the-art receding head hydraulic die-cutting machine. This machine is an ideal cutting solution for a wide range of flexible and semi-rigid materials, embodying high-quality manufacture and cutting-edge technology.

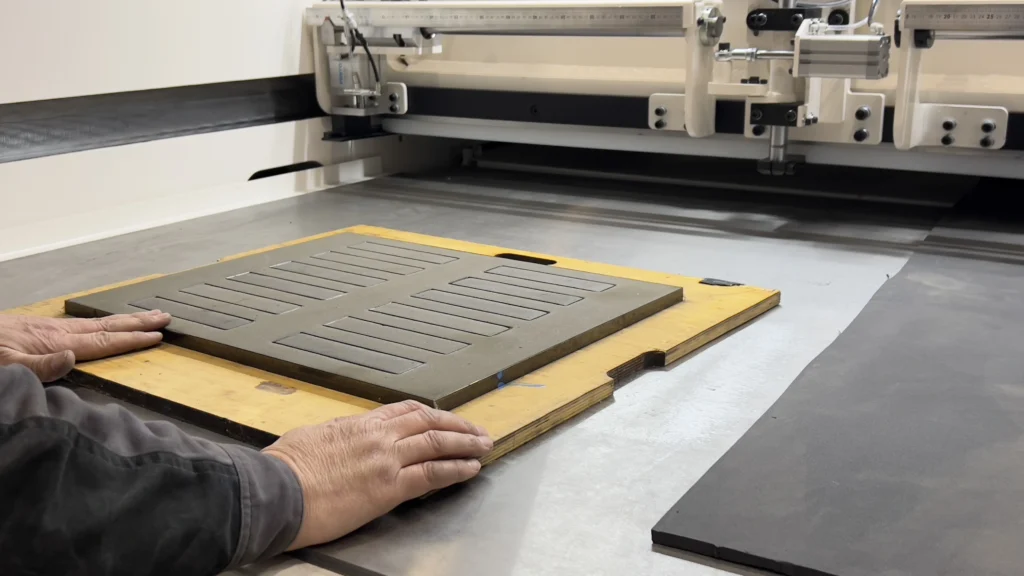

A horizontal moving beam moves forwards and back for each cut, driven by an electric geared motor, leaving the entire cutting area free and enabling the operator to position his die and remove the cut-outs.

If required, the die can be attached to the face of the beam and in that case, the operator collects only the cut out pieces. In other words, on this machine, the counterpunches can be situated either on the beam or on the rising table.

The return distance of the beam is adjustable on the tactile screen in increments of 100 mm (parametrable). The table rises vertically to meet the beam when the beam is in the forward position. This table applies the pressure, moved by two or four hydraulic cylinders beneath the table which apply balanced pressure at two or four points. This ensures that the table remains strictly parallel to the beam, wherever the cutting force is applied.

Our patented oil injection system operates through a main cylinder with check valves into the 2 or 4 table cylinders.

There is an EC certified cell barrier to ensure the machine’s safety system at the front, and guards at the back.

It is used for cutting soft materials with one or more thicknesses into rolls or sheets up to a width of 3000 mm.

Fields of application:

- Synthetics

- Textiles

- Leather

- Gaskets

- Foam materials

- Plastics

- Carpet

- Felt

- Rubber

- Etc.

The material can either be fed in from the front or from the back by, for example, using a double roller material feed.

The work area is completely protected with accessibility at the front for greater proximity to the material.

Features of the SA XPM Receding Beam Die-Cutting Machine

- Versatile Cutting Capabilities: Our receding head press design ensures a spacious cutting area, allowing operators to easily position dies and retrieve cut-outs.

- User-Friendly Interface: Equipped with a touch-sensitive, multi-language interface, this machine offers an operator-friendly experience, ensuring ease of use and increased productivity.

- Robust Construction: The SA XPM is robustly built with mechanical welding, guaranteeing durability and long-term performance in demanding industrial environments.

- Precision Cutting: This cutting equipment is designed for high accuracy, providing clean and precise cuts every time.

- High Production Rhythm: Capable of up to 10 cuts per minute, our machine ensures a high production rate without compromising on quality.

- Customizable Options: With a variety of options, the SA XPM can be tailored to meet specific client needs, making it a versatile solution for various industries.

Ideal for Multiple Sectors: Our hydraulic die-cutting press is perfect for a wide range of sectors, including automotive, furniture, medical, packaging, and more. It’s capable of cutting various materials such as rubber, cardboard, leather, foam, and plastics, making it a flexible solution for diverse industrial requirements.

Made in France – Quality Assured: Proudly designed and manufactured in France, the SA XPM receding beam die-cutting machine is a testament to superior quality and innovation in the field of industrial cutting solutions.

Contact Us Today: Discover the difference with our high-quality SA XPM cutting solution. Contact our sales team now!

Technical features

| Useful cutting power: | from 80 to 500 Tons |

| Speed of the beam, forward and back: | 52 m/mn |

| Accuracy of beam stop: | +/-5 mm |

| Stroke adjustable: | 20 to 120 mm (220 mm as an option) |

| Cutting speed: | 22 mm/s not adjustable |

| Daylight between table and beam (without die and without block): |

40 to 160 mm (250 mm as an option) |

| Height of the work surface: | 940 mm |

Options

- Material feeding systems

- Unwinders

- Mechanical posi-stops (on machine with 2 and 4 cylinders)

- System allowing to maintain the pressure (allowing to make thermocompression)

- Servo-motor on the beam allowing to obtain in front of an accuracy +/- 0.2 mm

- Block / die rotation systems under the beam or on the table

- Cutting on rectified tempered steel plate (with mechanical posi-stops)

- Heating plates

- Dimmable lighting

- Die-holder above the beam

- Die-holder under the beam

- Machine without front cover

- Remote control module

- Designer version

- Painting on request

Available versions

Range 2 cylinders: Working areas (mm) and powers (other working areas and other powers on request)

- 1600 X 800 – 80T and 100T

- 1600 X 900 – 80T and 100T

- 2000 X 800 – 80T and 100T

- 2000 X 900 – 80T and 100T

- 2400 X 800 – 80T and 100T

- 2400 X 900 – 80T and 100T

Range 4 cylinders: Working areas (mm) and powers (other working areas and other powers on request)

- 1600 X 900 – 130T/150T/200T/250T/300T

- 1600 X 1200 – 130T/150T/200T/250T/300T

- 1600 X 1500 – 130T/150T/200T/250T/300T

- 2000 X 900 – 130T/150T/200T/250T/300T

- 2000 X 1200 – 130T/150T/200T/250T/300T

- 2000 X 1500 – 130T/150T/200T/250T/300T

- 2000 X 2000 – 130T/150T/200T/250T/300T

- 2000 X 2500 – 130T/150T/200T/250T/300T

- 2400 X 900 – 130T/150T/200T/250T/300T

- 2400 X 1200 – 130T/150T/200T/250T/300T

- 2400 X 1500 – 130T/150T/200T/250T/300T